• Tipping Cylinder

• Lifting Cylinder of Furnace Cover

• Rotating Cylinder of Furnace Cover

• Lifting Cylinder

• Connect The Trolley Cylinder

• Depress The Cylinder

• Mast Cylinder

• Thrust Cylinder

• Lock Cylinder

• Cover Cylinder

Can be customized according to customer requirements.

(Bore diameter: 580mm/Rod diameter: 560/pressure14MPa)

(Bore diameter: 40mm/Rod diameter: 28/pressure14MPa)

(Bore diameter: 320mm/Rod diameter: 300/pressure14MPa)

Slide Gate or Rolling Slide Gate (SG or RS)

HYDROMASION® Slide Gates, Rolling Slide Gates, and Valves are the best solution for accurately controlling the flow of your materials. As with all HYDROMASION® products, they can be customized to fit your application’s needs. Product features include:

- One of the most common material handling devices.

- Start, stop or regulate product flow.

- Suitable for the finest powders to very large lumps.

- Self-cleaning blade supports prevent binding during blade movement

- RS offers sealed, re-greasable cam follower blade support system.

- SG offers fixed blade supports (polymer or steel) to reduce maintenance.

- Full perimeter seals contact the top of the blade surface only

- Assuring complete blade closure

- Increasing seal life

- Blades thickness evaluated for each application to insure minimal deflection.

- Hardened blades and seal retainers provide internal wear surfaces and offer long life.

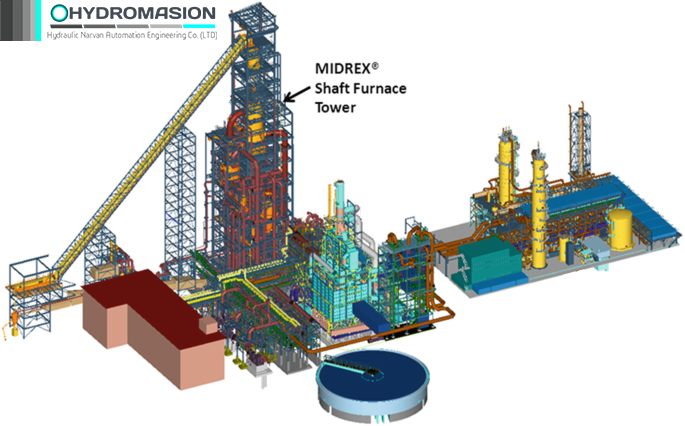

Hydraulic System of MIDREX

HYDROMASION® design and construction of hydraulic system to provide the required hydraulic power for Burden Feeders and Slide Gates with a maximum working pressure of 200bar, which is placed as a set in a room. The tools and elements used in Power Unit include the following:

- Rexroth variable piston pump, with pressure compensated and Remote control system made by Rexroth company.

- 90kW and 7.5kW electric motors made by VEM Germany.

- Oil circulation system including Rexroth series fixed vane pump.

+Hydraulic Cylinder for Upper burden feeder

+Hydraulic Cylinder for Middle burden feeder

+Hydraulic Cylinder for Lower burden feeder

+hydraulic Cylinder for Slide gate (with Cushioning)

vertical briquetting press line

HYDROMASION® design and construction of hydraulic system to Briquetting Press Line mainly compress metal chips such as metal shavings, copper shavings, copper swarfs, brass chips, copper turnings, aluminum chips, aluminum shavings, cast iron chips, various of loosen metal chips etc...

We can offer you two size of briquetting machine . for more information and details, please contact to our head office.

Horizontal briquetting press line

HYDROMASION® design and construction of hydraulic system to Briquetting Press Line mainly compress metal chips such as metal shavings, copper shavings, copper swarfs, brass chips, copper turnings, aluminum chips, aluminum shavings, cast iron chips, various of loosen metal chips etc...

These series of hydraulic briquetting presses are industrial machines designed to press metal chips into briquettes and operate in automatic mode..